Presentation 3 - November 28, 2018

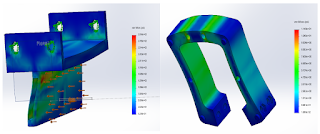

Today, most of the groups presented. Half-scale and small-scale were the only teams that were not able to present today. Both the solar team and the full scale bogey team showed improvement in the range of progress from their last presentation. For next week, our team should further prepare for the presentation. I was able to prepare all of our Solidworks FEA for the presentation. Our safety factors for the third rail support was 18 when it was acting as a cushion to the bogey switching tracks. It was 6.3 when it acted as a vertical support for the third rail, meaning that an additional switch support for the track would not be necessary as the piece will not fail under the force of one bogey. The Bracket had a safety factor of 16, meaning that it will still be able to hold up our track. The team is anticipated to further discuss if a bracket of half an inch may be enough for the support in order to reduce print time and save materials. The straight and dip rails both would not d