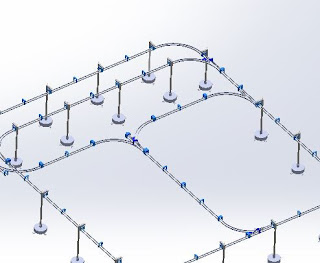

Track Bender and Presentation - October 31, 2018

Today our team presented our designs and calculations to the Spartan Superway team. Dr. Furman recommended that we continue to update the overall CAD file of the track so that we may have something more up to date. There is also the possibility of sand casting our hanger brackets instead of injection molding the, but this option is still just a thought. Our team also began on working to improve the design of the track bender. The problem we had with it was that: 1. The wheels used to bend the rails were not aligned. 2. The back wooden plank that is suppose to keep the rail straight was loose and would tend to lean side to side 3. The bottlejack platform was not large enough to keep it in place while bending. 4. The handle bar not being perfectly locked in place also added to the issue of rails not bending perfectly So we began to take it apart and leaned on flipping the mechanism on its side. This is so that when bending the rails, we would have a more stable bend and likely av...